Quality Assurance

Newstar leverages its years of industry experience and exceptional product quality to build an extensive global customer network. Our products are widely used in construction machinery, aerial work platforms, shipbuilding and heavy industry, mining, and aerospace, serving clients across Asia, Europe, the Americas, the Middle East, and over 30 other countries and regions worldwide. Since 2009, Newstar has provided more than 200,000 pcs of cylinders to JLG, Snorkel, Altec, Haulotte and other world-class manufacturers of aerial working vehicles and there is not any accident caused by the fault of our cylinders. Understanding that service excellence is inseparable from product performance, Newstar prioritizes ensured hydraulic cylinder quality by the following measures:

-

Strong Research and Development TeamThe product quality depends firstly on the engineer’s design. To design the product that suits the customer best, Newstar built a Research and Development Center with strong technical team. We can customize effective, environment friendly, and high quality product based on different requirements from customers.

Strong Research and Development TeamThe product quality depends firstly on the engineer’s design. To design the product that suits the customer best, Newstar built a Research and Development Center with strong technical team. We can customize effective, environment friendly, and high quality product based on different requirements from customers. -

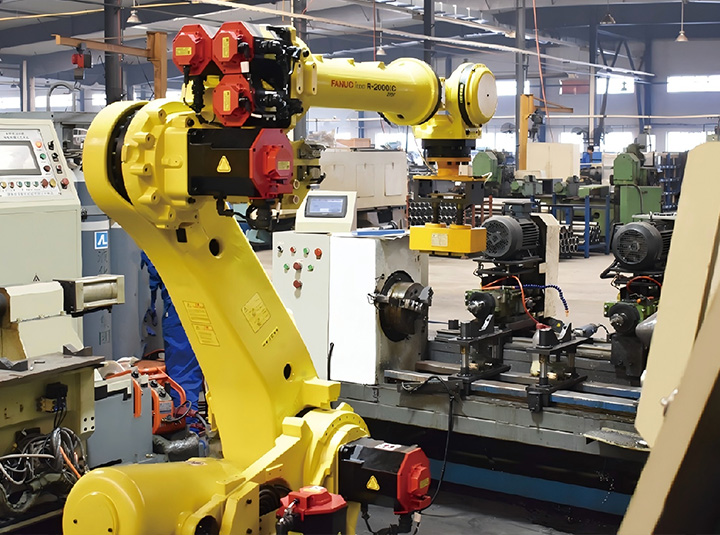

Advanced Production EquipmentNewstar's precision manufacturing capabilities are anchored in advanced production infrastructure, including:

Advanced Production EquipmentNewstar's precision manufacturing capabilities are anchored in advanced production infrastructure, including:

Multi-length Tube Processing Lines (3m, 2m, 1.5m & 1m configurations)

Intelligent Assembly Line

Equipped with PLC control system, touch panel and scanner. Automatically upload and download parameters to make sure the unique, controllable and timely data.

The servo pump sets make little noise and effectively improve the working environment. Servo pump station uses less hydraulic components and concentrates on the valve block to reduce leakage and increase stability.

The pump set can start and stop automatically according to the actual needs. Provide the corresponding pressure and flow rate accurately and quickly. Realize oil supply on demand and completely eliminate overflow loss.

Intelligent Test Station

Servo motor and sensor connected with closed-loop control. Test breakaway pressure, stroke, internal leakage, external leakage and proof pressure. And the pressure control precision within 0.5%.

Compact structure, easier to repair, automatic alarm when there is problem.

Stable performance, good consistency, high control accuracy. Using preset program control. Part of the control instruction is from the real time monitoring and the feedback of the process to make sure the accuracy.

The data generated by equipment operation and process can be recorded and saved automatically and the operation time will be accumulated automatically. The operators will be prompted to carry out maintenance when it is time to maintain.

Friction Welder

No smoke or noxious gas. No flatter, sparkle, arc light or radial. No welding electrode is needed. There will be no pinhole or slag.

Servo control, high precision, low energy consumption, low cost with the function of turning the burr and squeezed revers under high temperature.

Optional mechanical arm for automatic loading and unloading and optional positioning stop function to achieve relative angle welding.

Precision control with: Perpendicularity: ≤0.15mm, Length: ±0.5mm/2000mm and Symmetry: ≤0.3mm.

Eco-plating Line

This Eco-plating Line can make Eco-plating Line by abandoning the old idea of “releasing after meeting standard”. Newstar completely fulfilled the “Zero-Release” and initiated the new mode of recycling the waste gas and water. Organized zero-release means the relevant liquid and gas generated from production will be sealed separately in a special system going through a cycling process of using—collection—treatment—using, without any planned or organized discharge of solid, liquid or gas with pollutant to the outside.

With such Eco-plating Line,Newstar can do High Corrosion Resistant Chrome Plating, since it succeeded in developing the unique plating process and solution ingredients, filling the gap in China and reaching the world-class level. The product passed the inspection of the international famous inspection institutions SGS, with hardness of over 950HV and NSS of over 500 hours with thickness of 50~60 microns. -

Strict Quality ControlNewstar always puts the product quality in the first place and strictly complies with the standard of ISO/TS 16949 Quality Management System. With the use of five major tools of APQP, PPAP, FMEA, SPC, and MSA, Newstar combines the man, machine, material, method, environment and measurement. Starting from the material incoming inspection to the quality control during production, then to the finished product inspection at last to make sure every cylinder is qualified.

Strict Quality ControlNewstar always puts the product quality in the first place and strictly complies with the standard of ISO/TS 16949 Quality Management System. With the use of five major tools of APQP, PPAP, FMEA, SPC, and MSA, Newstar combines the man, machine, material, method, environment and measurement. Starting from the material incoming inspection to the quality control during production, then to the finished product inspection at last to make sure every cylinder is qualified.